MENUMENU

Industry

Power Generation

The power industry encompasses the production and delivery of electricity via central power stations and grid connectors. The industry is further subdivided into hydropower, waste to energy and thermal power. Typically, most businesses and households especially in developed nations require access to electricity. Demand for electricity is derived from the requirement of electricity in order to operate office equipment, industrial machinery, domestic appliances, lighting, heating, cooking and industrial processes. The power industry is typically viewed as a public utility.

Industry and Megatrends

Electricity is typically generated at a power station by electromechanical generators, primarily driven by heat engines fueled by chemical combustion or nuclear fission but also feasible when driven with kinetic energy generated from the movement of water and wind. There are seven fundamental methods of directly transforming other forms of energy into electrical energy, namely, static electricity, electromagnetic induction, electrochemistry, photovoltaic effect, thermoelectric effect, piezoelectric effect and nuclear transformation.

The industry mainly uses a range of generators, turbines and reciprocating engines to create energy or from the industry perspective, they called it power harvesting. These big equipment requires heavy processes to run and perform to meet high expectations in order to ensure a safe and productive environment.

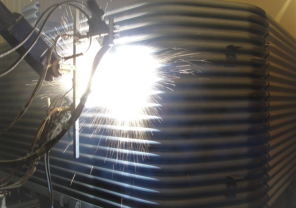

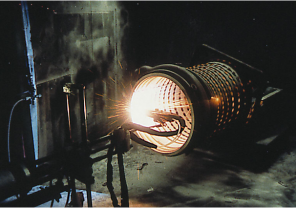

Dura-Metal worked closely with the industry to look into applications of the components in those generators, turbines and reciprocating engines where high durability and wear-resistant is required using Dura-Metal’s key hardfacing technologies such as welding and thermal spray methods. Dura-Metal is also continually working closely with industries’ key members in the joint development of parts’ durability to suit the power generation industries’ needs.

Some of our applications:

- Boiler tube coating

- Thermal barrier coating

- Turbine blade

- Turbine journal area restoration

- Complex carbide wear plate

- Pulverizer rolls & rings