MENUMENU

Durajet AF 6000 HVAF

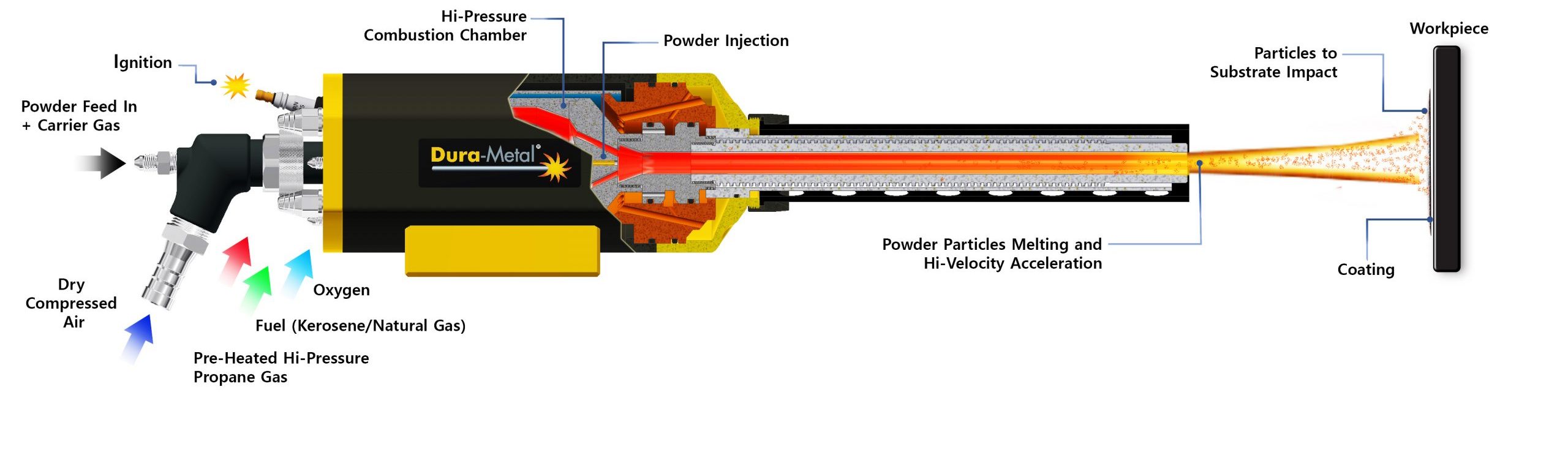

High Velocity Air Fuel (HVAF) torch system has revolutionized thermal spraying with a new level of coating quality. Compared to commercially available High Velocity Oxygen Fuel (HVOF) systems, the HVAF process offers significant advantages in two areas. First, the use of air for combustion in the AF 6000 HVAF System offers tremendous savings over the cost of oxygen in HVOF systems. Second, the HVAF torch is regeneratively cooled by the same air it burns, so it does not require water cooling as the HVOF system does. This eliminates the problems and expense of the cooling water and associated systems.

AF 6000 Thermal Spray System consists of the Model AF-6000 torch, Model AF-6000C Control Console, the Model DM 1200HP-PF Powder Feeder, and the cable and hose set.

AF 6000 Thermal Spray System uses up to 5 GPH (19 LPH) of kerosene, (A-1). This fuel is inexpensive, safe, easily stored, and readily available around the world. The system uses 140 SCFM (3948 SLM) of compressed air which cools the torch and supports combustion. The air requirement can be met using a standard 50 HP shop air compressor. If this is unavailable, Dura-Metal offers both motor and diesel-driven compressors.

Highlights:

▪ PLC Controlled (Allen Bradley)

▪ Automatic start-up and shutdown sequences

▪ Built-in Combustible Gas Detector

▪ Alarm and Status Indication

▪ With Operating Hour Counter

▪ Safety Manual Purge Control