MENUMENU

Design & Build Work Cell

Thermal Spray Cell and Automation

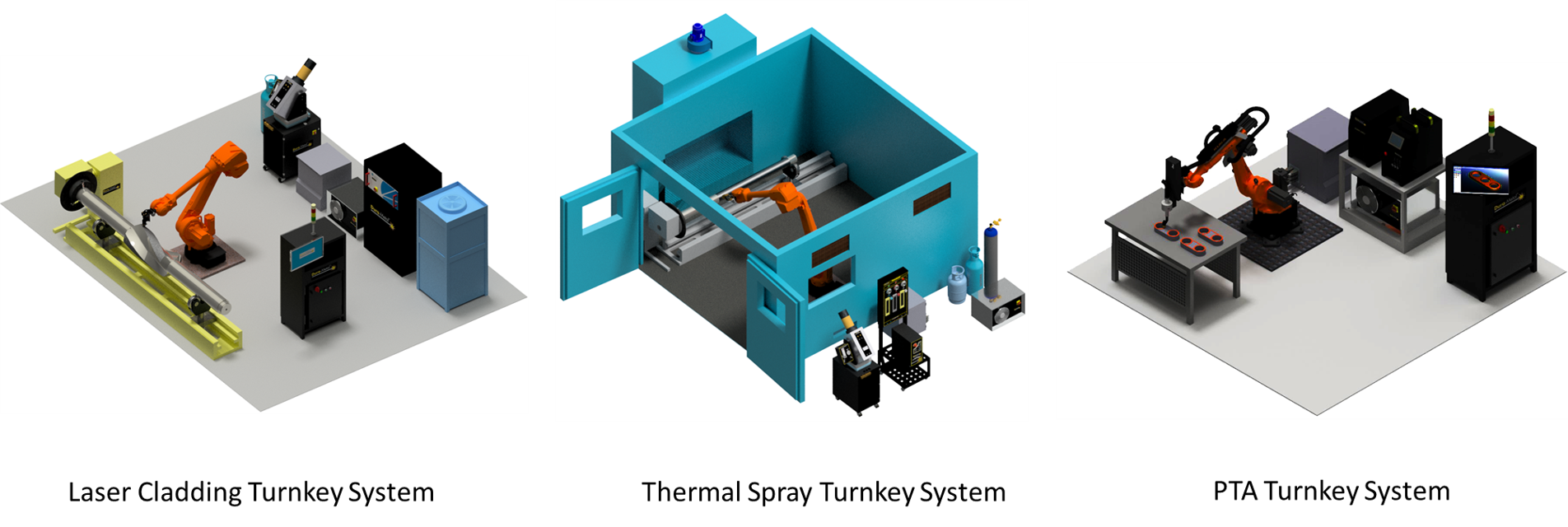

Dura-Meta is committed to providing you with a complete turnkey thermal spray solution for your specific needs. Our team of experts can equip a spray booth/work handling system to a high production thermal spray cell after analyzing your requirements and matching with the proper equipment thus optimizing your production and enhances quality.

Thermal spray automation is increasingly a necessity because of strict demands for coating consistency and the need to reduce coating cost. This provides us with an incomparable competitive advantage as we are able to offer the highest consumables quality in conjunction with innovative and reliable equipment range that tailors optimal solutions to individual requirements.

For precise & repeatable coatings, Dura-Metal offers:

▪ Surface preparation unit

▪ Automated spray cell system

▪ Integrated safety system

▪ Arc Spray & Flame Spray system

▪ Mass Flow Readouts Plasma Spray system

▪ HVAF/HVOF Spray system

▪ Acoustic chamber with dust collector

▪ Robotics integration for cladding and thermal spray

▪ Job manipulation system

▪ Laboratory support

▪ Operator training

▪ Technology support

Laser Cladding and PTA Work Cell

Dura-Metal have designed and manufactured a wide range of semi-automated and fully automated Laser and PTA equipment & fixtures for cladding applications. Our experienced mechatronics design engineers/technicians are trained to assist customers in their productivity and quality enhancement through innovative machinery designs and implementation.

Following are some examples of our successful deployment:

▪ PTA and Laser Cladding work cell for Oilfield Stabilizers

▪ Laser Cladding work cell for mining cylinder rods

▪ Column, Boom and Positioner for valve seats / spindles cladding for Marine Industry

▪ Working Handling / Cladding System for glass mould manufacturing

▪ ID cladding parts with PTA and Laser Cladding

Thermal Spray acoustic chamber & robotics installation