MENUMENU

Duralase Laser Cladding

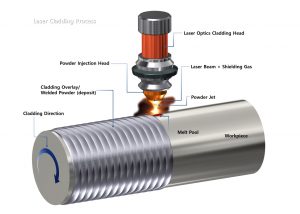

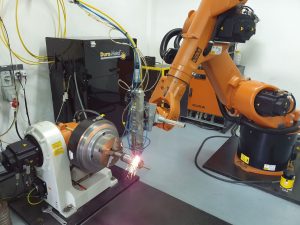

Laser Cladding process utilizes a precisely focused high power laser beam to create a weld pool into which metallic powder is applied to provide a wear resistance, corrosion resistance or impact performance protective coating. Dura-Metal offers complete line of industrial laser cladding equipment and powders that can be used to apply laser cladding coatings. The Duralase laser cladding system offers control and integration of the entire laser cladding process. We can also offer complete turn key solutions with booths, robots or PLC control and automation.

Highlights:

▪ Quality high power diode lasers

▪ High power efficiency

▪ Low investment and maintenance costs

▪ Outstanding reliability

▪ Mobility and compactness

▪ Ease of use and service

▪ Beam quality tailored to applications

▪ Low heat distortion

▪ Metallurgical bond

▪ Precise deposition

▪ Low dilution level (<5%)

▪ Low cracks

▪ High wear resistance

▪ Special Design I.D. Cladding Nozzle

▪ 36” reach into Tubular Part ( Minimum 4.5” I.D with viewing camera, Minimum 2.0” I.D without viewing camera)

▪ Water Cooled throughout

▪ Customized spot size/shape for optimum deposition rates

▪ All water, powder feed, & electrical are internally routed

▪ Optional camera viewing system available

Related Videos:

DM Tech centre application support | DM Tech centre ID cladding trial | Glass mould manufacturing |

Laser cladding on roller | Rebuilding on cylinder rod | Agriculture Application |