MENUMENU

Fusejet PLUS Powder Welding

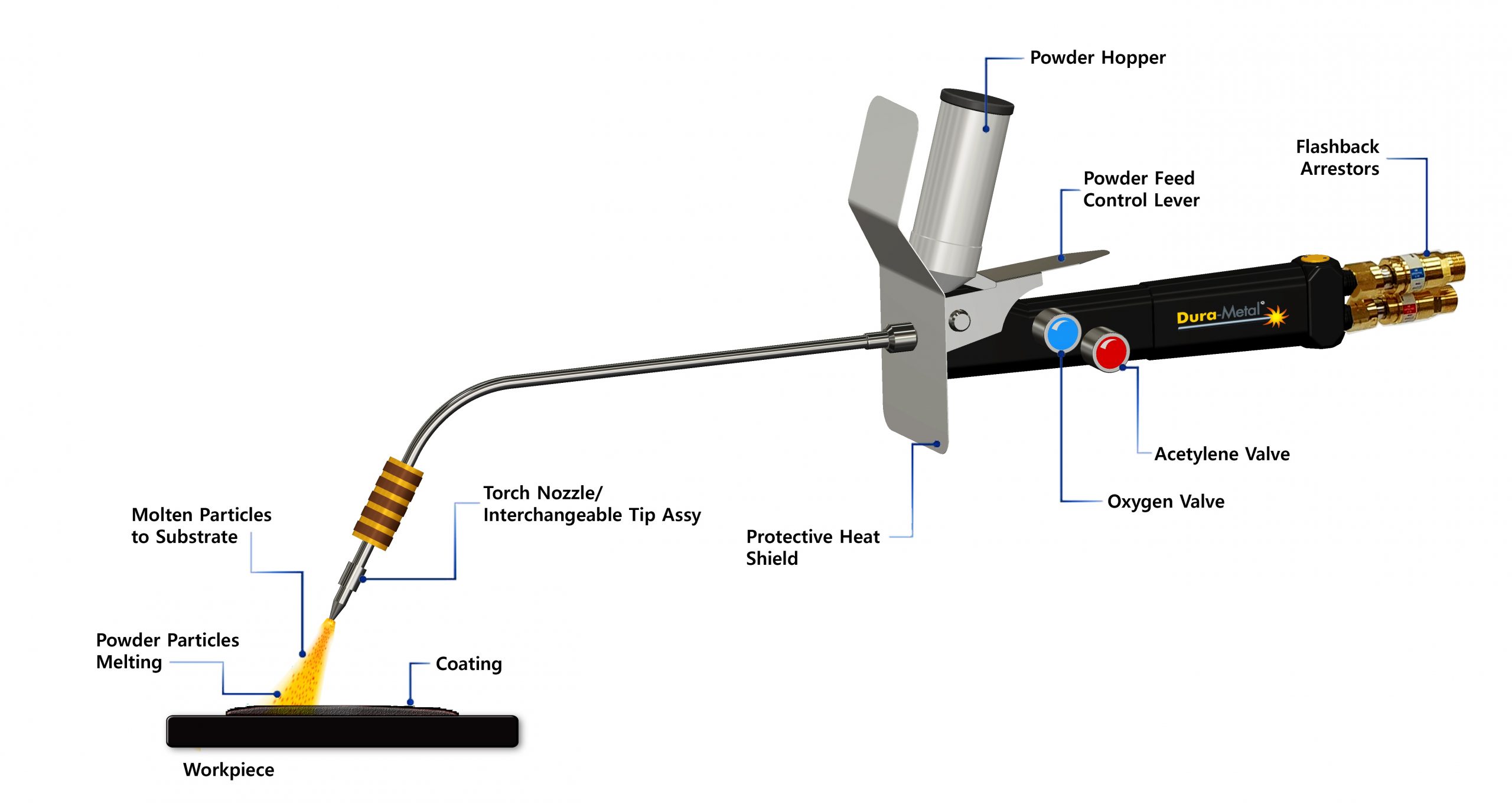

The Fusejet PLUS powder welding torch is a robust manual powder welding system for surfaces and over edges. It is also applicable in delivering coating on larger parts when used with a custom-designed extension assembly and tungsten carbide tip that enables high powder deposit onto substrate. Fusejet PLUS offers premium-grade coatings that not only last but is also price competitive. The coating is capable of protecting against abrasion, corrosion, erosion, and cavitation that can be produces permanently and economically for low costs.

Self-fluxing metal powder (Nickel & Cobalt Alloy, Tungsten Carbide Blend) are sprayed and melted into the surface by a gas/oxygen flame to attain coating hardness ranging from 25-65 HRC.

The following basic materials can be coated:

Stainless Steel, Grey Iron, Spheropheroidas Graphite Iron, Annealed Cast Iron, and Alloy Steel

Highlights:

▪ Modular design

▪ High level of operational safety

▪ Easy fit welding / heating attachments

▪ Powder cartridges reduce set-up time

▪ Easy to change in the field of application

▪ Easy usage for difficult to reach components

▪ Tungsten Carbide inserts available (optional)

▪ Accessories are easy to fit and to adjust

▪ Cost efficient operating materials (Acetylene, Oxygen)

▪ Quick action couplings & safety devices for the gas hoses

▪ Hose packages and Pressure regulators (optional)

▪ Cost efficient by using standard components and standard spare parts

▪ Gas On / Off mode capability at handle = ease of usage during production

▪Extension assembly with C5 or C6 tungsten carbide insert for high powder deposition rate. (optional)