MENUMENU

Plasweld 7000 PTA

For more than 20 years, Dura-Metal has been working successfully in the field of Plasma Transferred Arc ( PTA ) welding – particularly in that of Plasma Hardfacing.

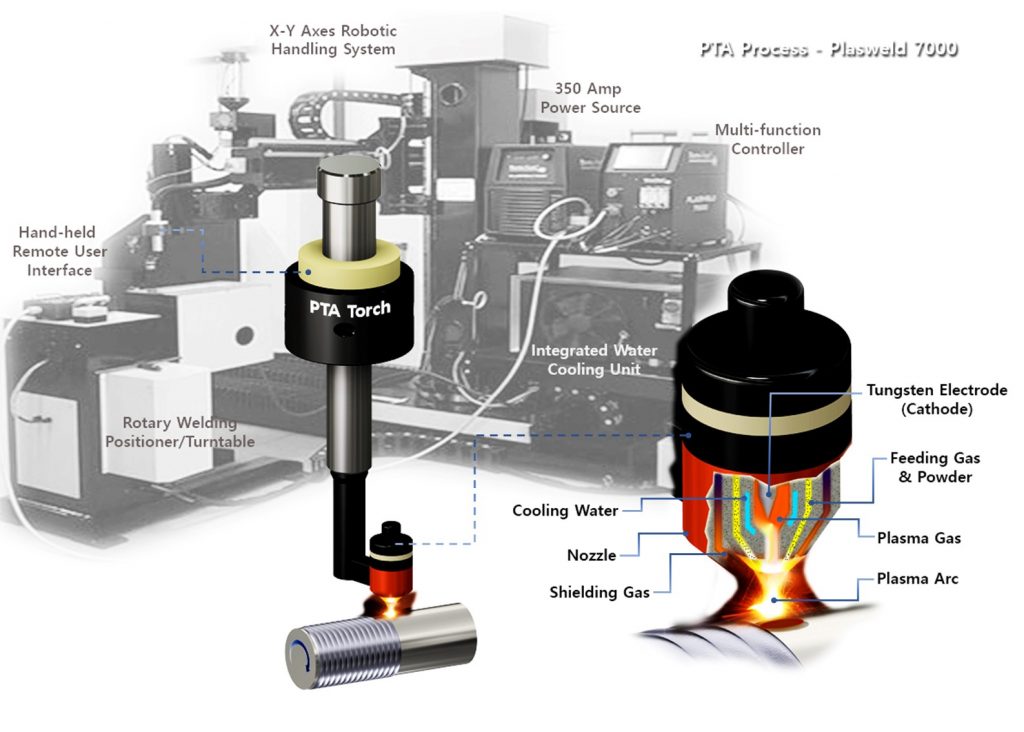

We are pleased to introduce the state of the art PLASWELD 7000 Plasma Transferred Arc (PTA) system. It is a high quality, modular and robust system with hand-held deposition capability. It is engineered for accuracy and simplicity for operation. The PLASWELD 7000 system uses argon gas to deliver a controlled amount of powdered metal into an argon-7% hydrogen gas shielded plasma transferred plasma column so as to produce metallurgical bonded, wear-resistant coatings to the workpiece. Accurate control of the process parameters is made possible through a PLC Controller, these parameters include powder feed rate, current input, gas flow rates, upslope and downslope, and arc voltage.

When hooked up with suitable work handling equipment – the system will produce precise deposit profiles with minimal base metal dilution. The resulting coatings are assured to provide homogenous, optimal wear, and corrosion resistance overlays. All these benefits are incorporated into a modular and robust system designed to be flexible and user-friendly. Simply one of the best PTA system that the market can offer.

Highlights:

▪ Robust 400 Amp power supply and allows for any input voltage hook up ( 208V – 575V)

▪ Consistent easy arc start and soft arc transfer to the substrate

▪ A unique power source designed protects internal electrical components from airborne contaminates. Also, the cooling system operates only when needed, reducing noise, energy use, and the amount of contaminants pulled through the machine, thus extending product life

▪ Extremely stable welding current and minimum heat-affected zone during welding

▪ Fully automated function allows for a single button to turn the system On and Off without any sequence being followed

▪ Ability to store up to 250 weld programs including voltage, amperage, powder feed rate, oscillation. All may be adjusted from a remote pendant

▪ Build-in torch oscillation unit

▪ Build-in arc voltage controller ( AVC ) – automatically reduce or increase the arc length due to surface irregularities

▪ Automated or semi-automated machine-mount installation or as a standalone hand-held installation. It can be easily integrated into a wok handling or robotic system

▪ Error prevention by constant monitoring and measuring of coolant and gas flow

▪ Shortcut to needed parameters may be reached with one click or change with remote pendant

▪ Smallest ID torch in the market ( Dia < 1.5” )

▪ Handheld torch capability

Related Videos:

Shovel Teeth | Powder maker technical centre | < GET overlays |

DM 150 ID Weld |