MENUMENU

Wire Flamejet Single Wire Flame Spray

Wire Flamejet is a robust and user-friendly wire metal spray system use for spraying both ferrous and non-ferrous material. Key applications are restoring worn-out components, conductivity, and anti-corrosion coating.

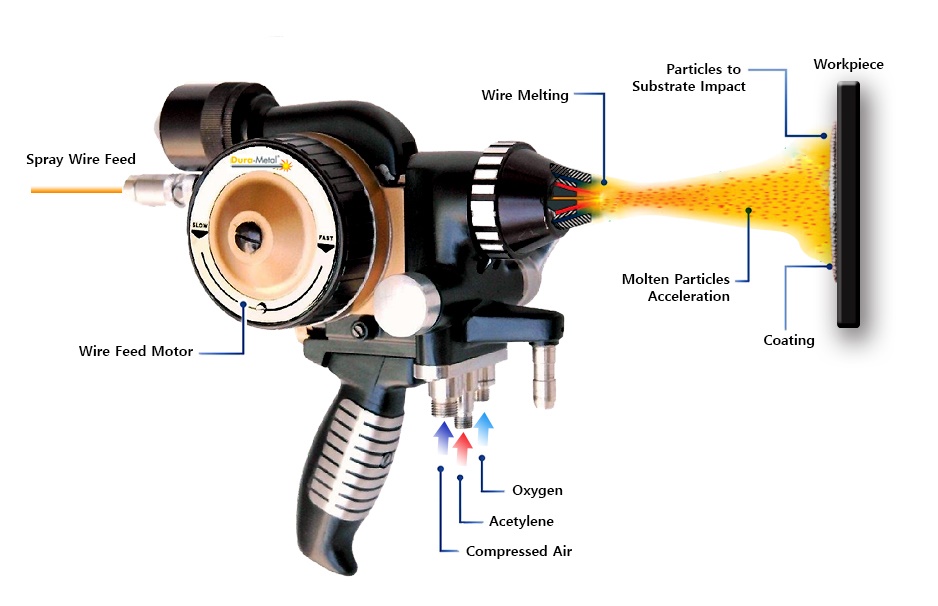

The wire is fed into the front torch through an air-driven turbine. Fuel gas like acetylene, LPG, or Propane and oxygen is properly and safely mixed in the siphon plug head assembly which in turn provides a combustible heat source. The molten metal is atomized and propelled by means of compressed air in the form of fine metal spray for coating on job surfaces.

Generally suitable for all metals and metal alloys in wire form for spray coating i.e. Zinc, Copper, Aluminium brass, Bronze, Steel, Stainless Steel, Molybdenum, Nickel Alloy, etc. The standard wire used for the flame spray is generally 3.2mm or 4.8mm.

The Wire Flamejet system comprises of the following:

▪ Wire flame spray gun

▪ Gas Flowmeter

▪ Gas control unit

▪ Air control unit

▪ Wire reel stand with a straightener

▪ Hose unit

Optional items:

▪ Extension nozzle

▪ Trolley with reel stand

Other series of Wire Flame Spray System:

| Wire Flamejet-PM | A robust pneumatic version system mainly used for onsite sensitive applications like shipbuilding where electrical and electronic items are prohibited on board during operation. |