MENUMENU

Industry

Steel Industry

The modern steel industry began since the late 1850s and has been the foundation of the world’s industrial economy. The steel industry is at the core of the green economy, in which economic growth and environmental responsibility work hand in hand.

Industry and Megatrends

Steel production processes are dependent on the product mix, availability of raw materials and energy supply. Key characteristics of the three main processing methods include:

- Blast Furnace / Basic Oxygen Furnace where pig iron is produced using primarily iron ore (70-100%) and coke in a blast furnace, and then further turned into steel in a basic oxygen furnace. Because of the inclusion of coke making and sintering operations, the process is energy-intensive.

- Scrap/Electric Arc Furnace for scrap for the iron input. Usually has significantly lower energy intensity compared to Blast Furnace due to the omission of coke making and iron making processes.

- Direct Reduced Iron on iron ore and/or scrap for the iron input. Depending on the size, fuel and ore characteristics, energy consumption can still be less than Blast Furnace.

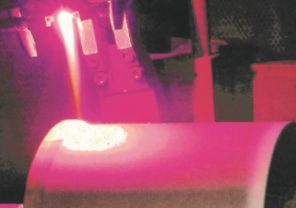

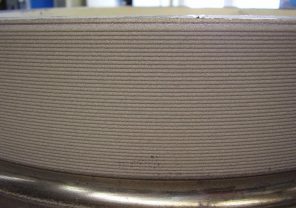

Dura-Metal supported the industry with the introduction of surface coating technologies using welding and thermal spray methods. The intent of hardfacing is to enhance the component parts’ profiles while at the same time, maintaining their performance in the production conditions. Our product range includes welding & coating equipment and consumables as well as product development on stainless steels, high-strength low-alloy and non-ferrous materials (copper, nickel, aluminium, titanium). In addition, Dura-Metal plays a vital role in the joint development of parts for the various applications in the Steel industry.

Some of our applications:

- Looper roll

- Guide roller

- Hearth roll

- Pinch roll

- Zinc bath roll

- Spray and fuse on rollers