MENUMENU

DM 3100-PS Plasma Spray

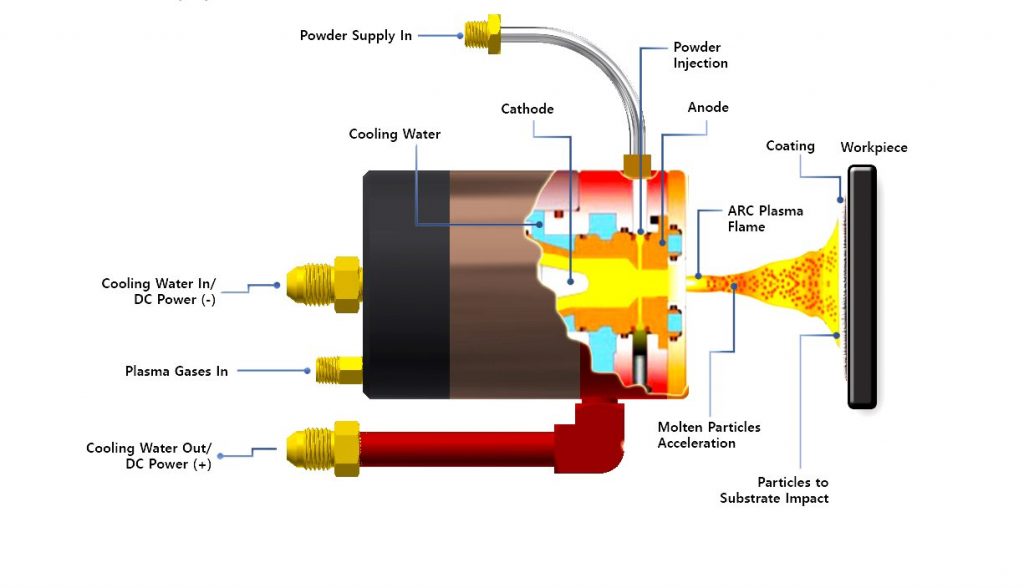

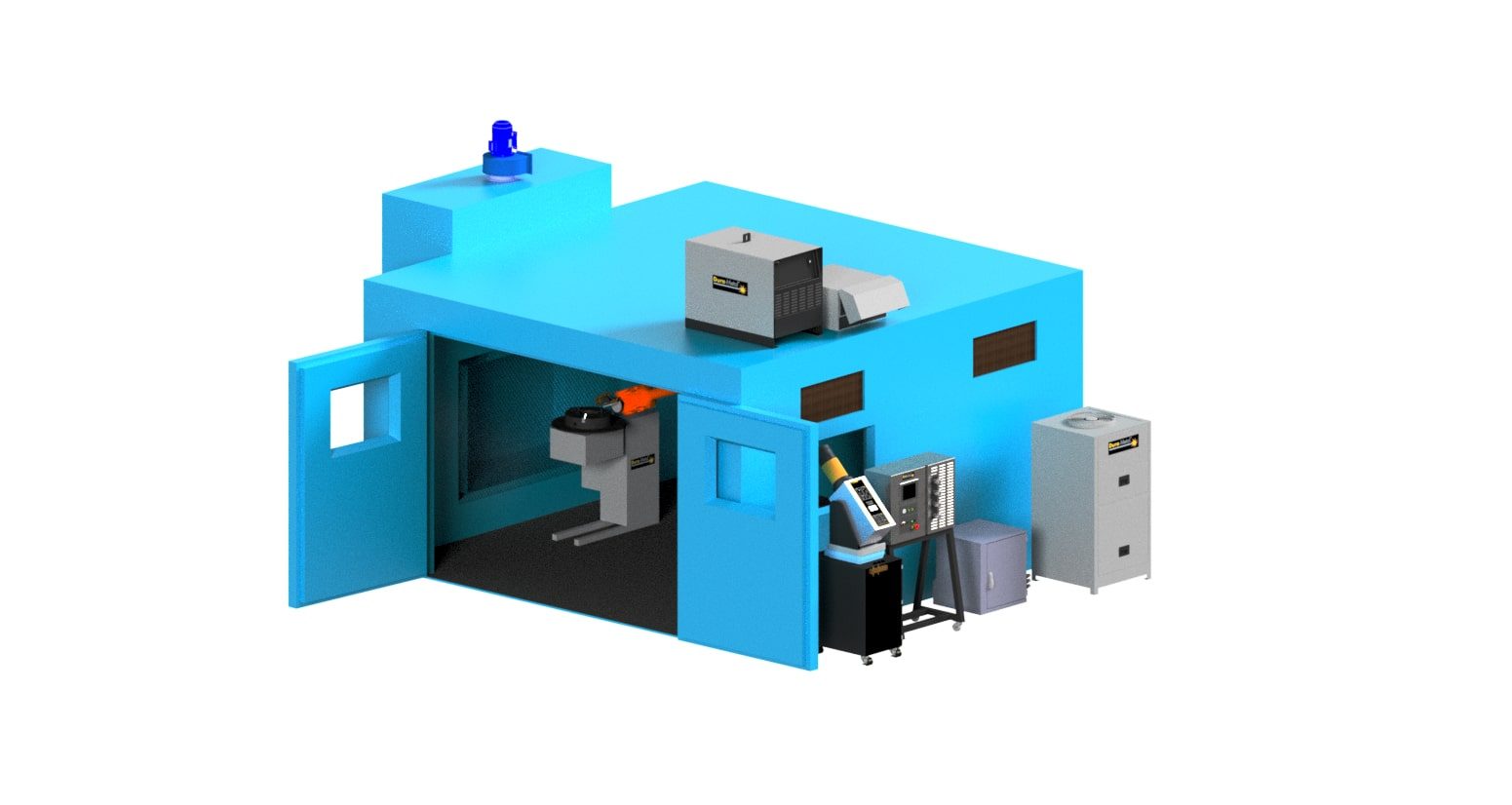

The DM 3100-PS Plasma Spray System is designed and built using materials of the highest quality together with the latest technology and production methods available to deliver consistent high-quality coatings. The DM 3100-PS is also designed with safety and user-friendliness features that surpass industry expectations. It features a built-in user-operated Safety Purge System and also has the capability to run safely on Hydrogen as a secondary gas. Furthermore, all of the components in the system are designed in a way such that all electrical signals and power entering and leaving the DM 3100-PS console during purging are deactivated. This feature ensures that dangerous conditions prior to purging will be eliminated.

With a PLC and touch screen control, the user can take advantage of the many features that aid the plasma spray process. The DM 1000 power supply’s amperage is closed-loop controlled by the console, which monitors the voltage at the power supply and plasma torch. Using the DM 1200-PF powder feeders, the DM 3100-PS console commands feeders offers closed-loop RPM feeders. The DM 2000 Arc starter, a solid-state high frequency ignition unit which is powered by the console, requires no adjustment to operate. The DM 4000 heat exchanger, a 10 ton refrigerated chiller, is activated by and feeds its alarm directly to the DM 3100-PS console. The console also offers optional interface features to incorporate customer-supplied devices, such as booth ventilation switches, external E-Stop devices and manipulation control.

Highlights:

▪Touch screen control

▪ Safety purge system

▪ Automatic and manual mode

▪ Mass flow readouts

▪ Critical orifice repeatability

▪ Maintenance screens alarm

▪Series of built-in features to achieve high-quality plasma coatings

|