MENUMENU

Durajet HV 3000 HVOF

For more than 20 years, Dura-Metal has been working in the field of HVOF coating to restore worn out parts and also with OEM to develop wear resistance coating applications.

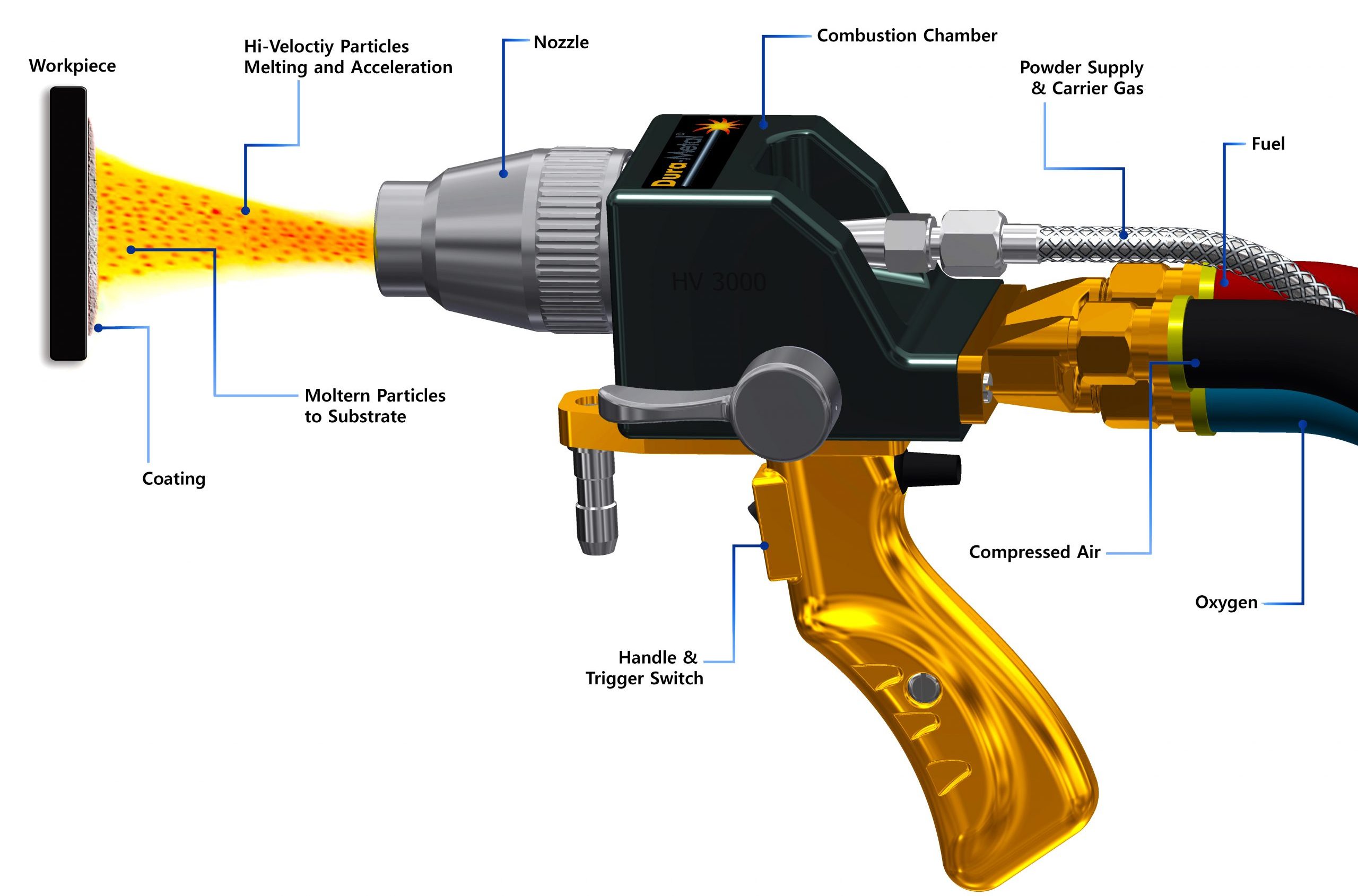

We are pleased to introduce the Durajet HV 3000 HVOF system. It’s economical, robust, lightweight, and of excellent quality. Durajet HV 3000 powder thermal spray system melts metallizing powder by heat generated through the combustion of fuel gas and oxygen. The metallizing powder is fed at a regulated speed to a flame-spraying torch that may be hand-held or motion-controlled. A continuous flow of compressed air surrounds the flame, atomizes the molten metal, and disperses it over the surface of the object to be coated. The spraying torch may be guided by hand for spraying large or intricate pieces; for production work, the torch may be mounted to programmable equipment, such as an x-y manipulator or a robotic arm. The HV 3000 system also comes with an optional add on, water cooled jacket (HV-JET HYBRID ASSEMBLY). This module will increase the torch thermal efficiency and also powder depositing efficiency – resulting in high-density coatings. This low capital HVOF equipment is an ideal system for small and medium size jobs shops.

We also offer model HV 3000-A auto-start HVOF system. It is PLC control with I/O signals or commands for turnkey integration.