MENUMENU

VRC Cold Spray System

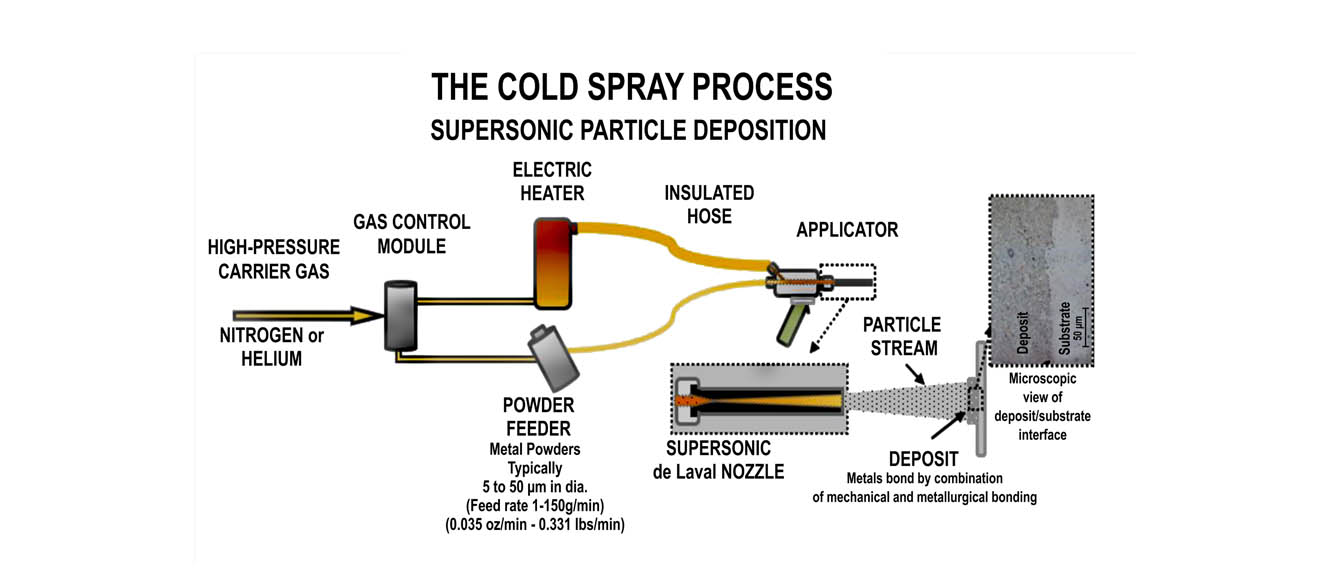

VRC Metal Systems, also known as “cold spray”, is the upcoming global leader in supersonic particle deposition and other advanced manufacturing process technologies.

The majority of the world’s leading cold spray teams are using the VRC high pressure cold spray system to advance their research on obtaining the highest deposition properties and pushing the envelope on advanced recipes and hybrid coatings. The high-pressure system deposits similar and dissimilar metals on most metallic surfaces even in previously impossible heat sensitive applications. VRC’s supersonic cold spray equipment enables innovative solutions for repair, additive manufacturing and coatings for many industries including aerospace, energy, shipping, mining, and oil & gas.

Dura-Metal in partnership with VRC offers full turnkey Cold Spray system. Our mission is to provide innovative, reliable metal deposition, automation technologies and powders application know-how to give our customers market leading capabilities.

Our turnkey high-pressure cold spray systems provides coatings of the highest quality with portability that differentiates us from our competition. Furthermore, we can apply high pressures and temperatures either by robot or patented hand-held applicator. The Gen III and Raptor cold spray system is the only high pressure, portable, and hand-held capable system in the world. It is also the only high-pressure system that can reach into diameters as small as a coffee cup. VRC has played an integral part in the approval of the repair process by using our high-pressure cold spray to repair Army helicopters, Navy submarines and the B-1B Bomber in the Air Force.

Dura-Metal will partner with you in repair and restoration of aerospace, marine and industrial components including but not limited to Aluminium, Magnesium, Titanium, Niobium and Inconel.

|

| Cold Spray Turnkey system with acoustic chamber and spray booth |